Equipment

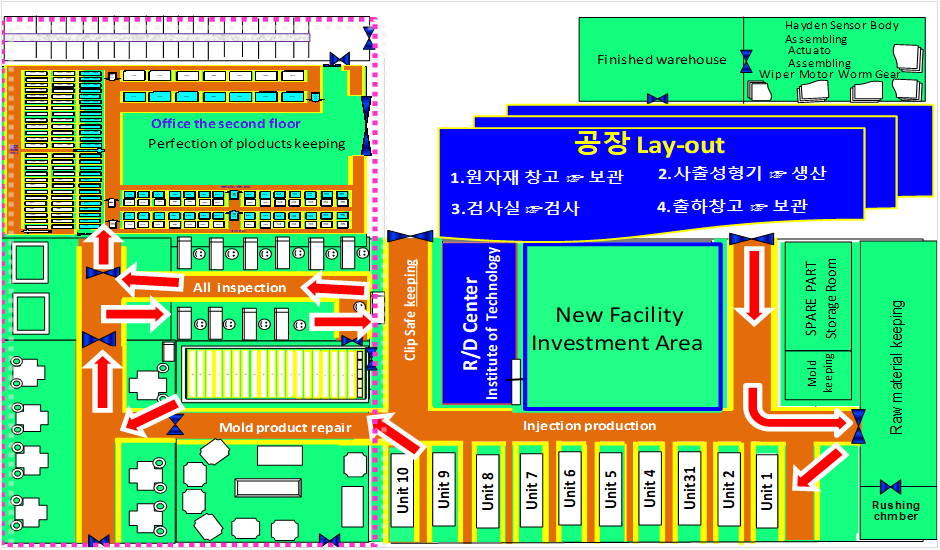

Factory Layout

Production Process

- 1 Receiving Original Material

- 2 Import Inspection

- 3 Raw Material Warehouse(Storage)

- 4 Injection Molding Machine(Production/Process Inspection)

- 5 Storage

- 6 Assembly

- 7 Laboratory(Shipment Inspection)

- 8 Warehouse(Storage)

- 9 Shipment

Production Facilities

-

Injection

Elec-Mold Machine

100 TON 4Unit -

Injection

Mold Machine

120 TON 2Unit -

Injection

Mold Machine

100 TON 2Unit -

Injection

Mold Machine

80 TON 2Unit -

Injection

Automatic extractor

10Unit -

Injection

Roader

10Unit -

Injection

Material drier

10Unit -

Injection

Low-speed crusher

10Unit -

Injection

Mixer

1Unit -

Injection

Water Heater

4Unit -

Assembly

C-CLIP Auto Assembly Large

5Unit -

Assembly

C-CLIP Auto Assembly Small

2Unit -

Mold

Electrical Discharge Machine

2Unit -

Mold

Milling Machine

3Unit -

Mold

Grinding Machine

1Unit -

Mold

Lathe Machine

1Unit

Inspection Facilities

-

Non-contact

VIDEO META

HEXAGON 1Unit -

Detailed measurement

Projector

Mitutoyo 1Unit -

Dimension measurement

Digital V/C

Mitutoyo 13Unit -

Detailed measurement

Micrometer

Mitutoyo 3Unit -

R measurement

R-Gage

2Unit -

Pitch measurement

Pitch Gage

2Unit -

Angle measurement

Protractor

1Unit -

Height measurement

Height gauge

Mitutoyo 1Unit -

Moisture meter

Moisture meter

AND MX-50 1Unit -

Thermo-hygrostat

DaeSeongTestr 1Unit -

Salt spray tester

DaeSeongTestr 1Unit -

Tensile Compressive

UTM Tester

1KN 1Unit -

Camera View

Vision Tester

HwaIn FA 2Unit